Home › Markets › Wine › Fermentation › Enzymes › Lysozyme

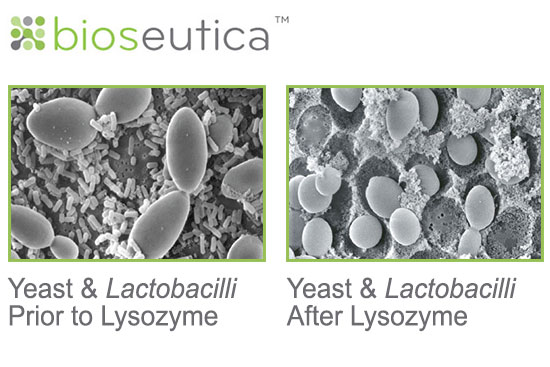

Lysozyme to Combat Wine Spoilage

It is recommended to add lysozyme to the grape must as early as possible at low levels between 100 and 150 ppm (10-15 g/hl). This allows early inhibition of some of the organisms that cause stuck and/or sluggish fermentations that can increase production of volatile acidity. These low levels of lysozyme will also control the development of indigenous bacteria, thus preventing premature malolactic fermentations and allowing the alcoholic fermentation to progress smoothly.

When using lysozyme to treat a sluggish fermentation, add it to the must at a level of 250 to 350 ppm (25 to 35 g/hl).

If a wine begins to develop volatile acidity as a result of lactic acid bacteria activity, an immediate lysozyme dosage of up to 250 ppm (25 g/hl) will assist in reducing the bacterial count and help bring the volatile acidity production under control.

Lysozyme will not inhibit acetic acid bacteria.

Lysozyme Helps Control Histamine Production in Wine

In general, biogenic amines (histamines) do not pose a major health risk for consumers; however, in some individuals histamine can trigger harmful or severe effects, known as false food allergies.

Histamine can be produced by some types of bacteria in fermented food, and ethanol in wine may inhibit the metabolism of histamine, allowing further increase of histamine levels in the body. Recently, some large wine retailers have set a limit of 10 ppm histamine in the wines they will sell.

In studies, the formation of histamine and other biogenic amines was mainly due to some strains of Pediococcus damnosus. Some strains of Lactobacillus and Oenococcus can also produce histamine.

Lysozyme is effective in controlling the growth of bacteria which are responsible for histamine production.